유한 요소법을 이용한 FLYWHEEL 변형 및 응력 해석 PROCEDURE 개발

페이지 정보

작성자 애니윈 작성일11-03-28 15:37 조회8,654회 댓글0건관련링크

본문

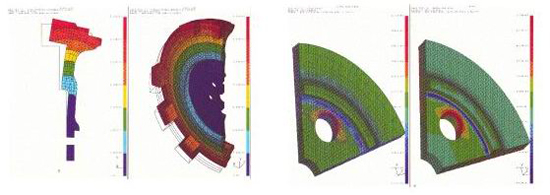

In this paper, we introduce procedures of advanced application of computer simulation technique using Finite Element Method to evaluate excessive deformation and stress level of flywheel during manufacturing and engine running mode. Shrink fitting of ring gear on the flywheel induces excessive deformation, and it exerts bad influence on the flatness of clutch face and assembling the flywheel and clutch assembly.

The application of our computer simulation techniques using Finite Element method easily evaluate deformation of the flywheel and play important role in optimizing the flywheel. Also, this technique provide another tool of evaluating stress distribution and stress level during engine running mode. With those stress results, it is possible to predict the critical area, safety factor and point of stress concentration.

This technique has shortened development period and reduced cost to evaluate deformation and stress analysis of flywheel at the design stage and trouble shooting stage.

The application of our computer simulation techniques using Finite Element method easily evaluate deformation of the flywheel and play important role in optimizing the flywheel. Also, this technique provide another tool of evaluating stress distribution and stress level during engine running mode. With those stress results, it is possible to predict the critical area, safety factor and point of stress concentration.

This technique has shortened development period and reduced cost to evaluate deformation and stress analysis of flywheel at the design stage and trouble shooting stage.

댓글목록

등록된 댓글이 없습니다.